Getting to Net-Zero Production: Part 6

The introduction of mobile Battery Energy Storage Systems (BESS) has led to a paradigm shift in how power is sourced, distributed, and managed on movie sets and in live events. In part one of this series (18 Sep 2024), we discovered that it is possible to get to net-zero production with mobile BESSs that can be paralleled to increase capacity and runtime. In part two (17 Mar 2025), we discovered that the “hard” power of BESSs eliminates the need to isolate non-linear loads on separate power sources – greatly reducing the number of generators required. In the previous part (17 Mar 2025) we looked at how we size power sources for loads under this new paradigm. In this part, we will explore another aspect of this new paradigm: the application of electrical engineering concepts to sizing BESSs to power basecamps.

This part is as much a call-to-action, as it is an exploration of the benefits that can be gained by using

two methods used by electrical engineers to size power systems for commercial and residentail buildings - Demand Factor and Diversity Factor – to the sizing of BESSs for motion picture basecamps. It is a call to action, in so far as, deriving Demand and Diversity Factors for basecamps will require detailed load profiling of more basecamps than the two I have profiled so far. In my opinion, profiling more basecamps is warranted because deriving a Demand and Diversity Factor for basecamps will, not only greatly simplify sizing BESSs for basecamp, but also make them more viable as an alternative sustainable power source.

The importance of deriving Demand Factors and Diversity Factors for motion picture basecamps cannot be overstated. If confirmed through the profiling of multiple basecamps, a Demand Factor and Diversity factor for basecamp will provide a quick and easy method for sizing BESSs for the ever-changing elusive power demands of basecamps. For instance, we will be able to determine in advance, and with accuracy, the size of the inverter required for the complicated compound loads of basecamps by taking the total connected load (which can be easily ascertained from the vendor for the trailers), and multiplying it by the Demand Factor, to get the probable maximum basecamp load the inverter must support.

To determine the amount of stored energy required to power the “on”- again, ”off” - again loads of basecamp, we will be able to take this probable maximum load, divide it by the Diversity Factor, to get the “sizing load.” Multiplying the sizing load by the hours of operation, will give us a fairly accurate estimation of the amount of stored energy required to power the basecamp for the day.

Taken together, these methods will assure that the BESS will be neither undersized (risking overload), nor oversized (which would increase costs unnecessarily). By applying a universal Demand Factor and Diversity Factor to the connected loads of basecamps will take the risk out of using BESSs – making them a viable source of sustainable power.

To successfully deploy sustainable power sources like BESSs requires that we think about production power in a fundamentally different way – more like an electrical engineer. Sizing rules for diesel plants are simple: use the maximum current on any leg to calculate the size of the plant required. Sizing BESSs is complicated by how they generate power and the elusive power demands of basecamp.

BESSs only generate power when called upon by a load. They don’t ‘idle’ like an internal combustion (IC) generator and don’t produce power whether there is a load consuming it or not. When there is no load, a BESS is chemically inert. It only converts stored chemical energy to electrical energy when demanded by a load. This has a significant impact on how we go about sizing BESSs to power basecamps. Where a continuous load like set lighting will rip through the energy stored in a BESS, their stored energy lasts a lot longer when loads are cycling “on” and “off” as they do in basecamp. This paradigm shift (BESSs only generate power when called upon by a load) also permits us to rate the ampacity of a BESS higher when powering basecamp than when powering set.

COP vs. Prime Ratings

Ratings for a power source are defined in ISO 8528 and ISO 3046. They consist of a rating for Standby Power applications, Prime Power applications, Continuous Operation Power applications (COP), and Limited Time Running Power applications (LTP). Each rating represents the source's ability to support loads under those specific conditions without overheating or being damaged, which makes them important when sizing a power source for a particular application.

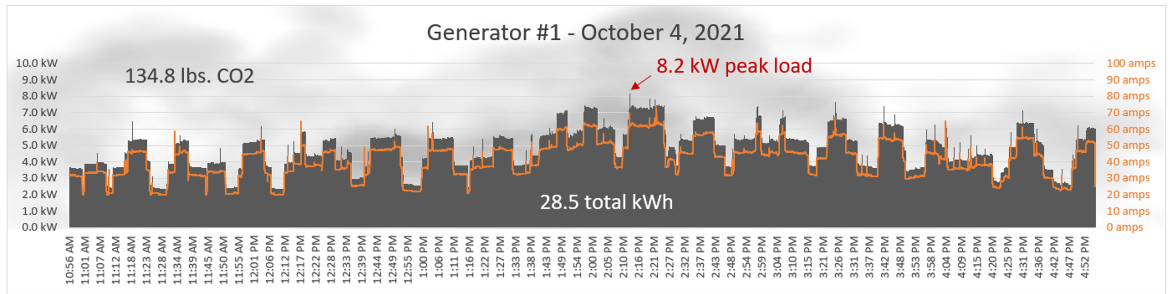

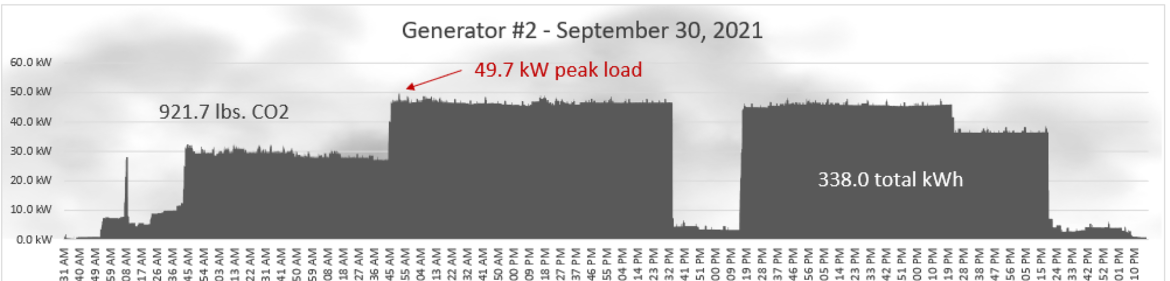

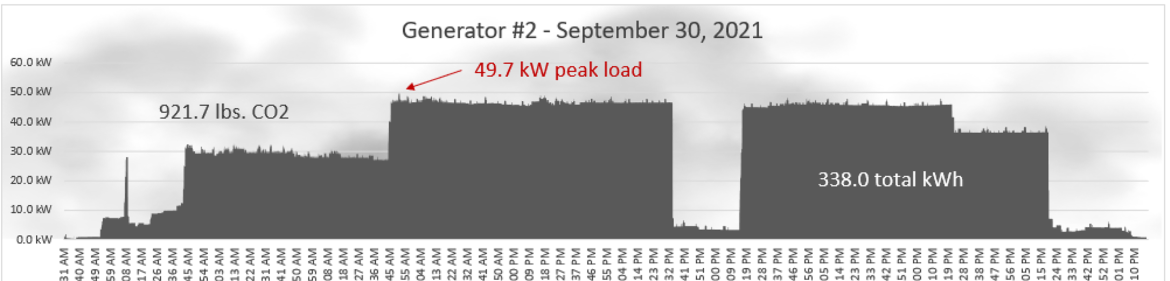

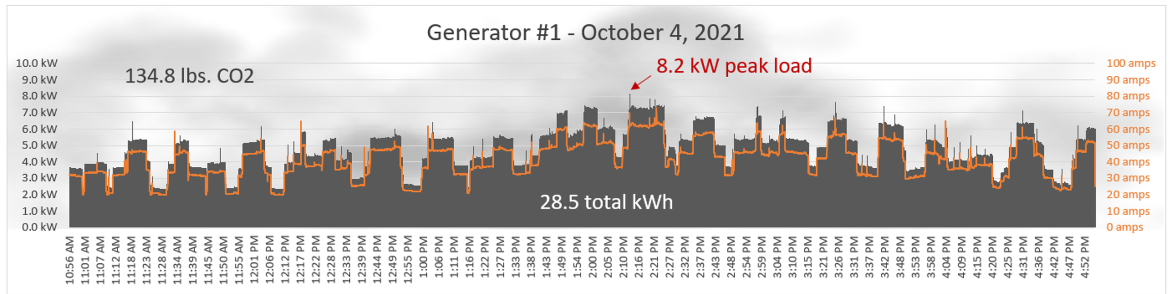

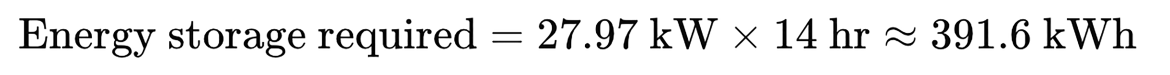

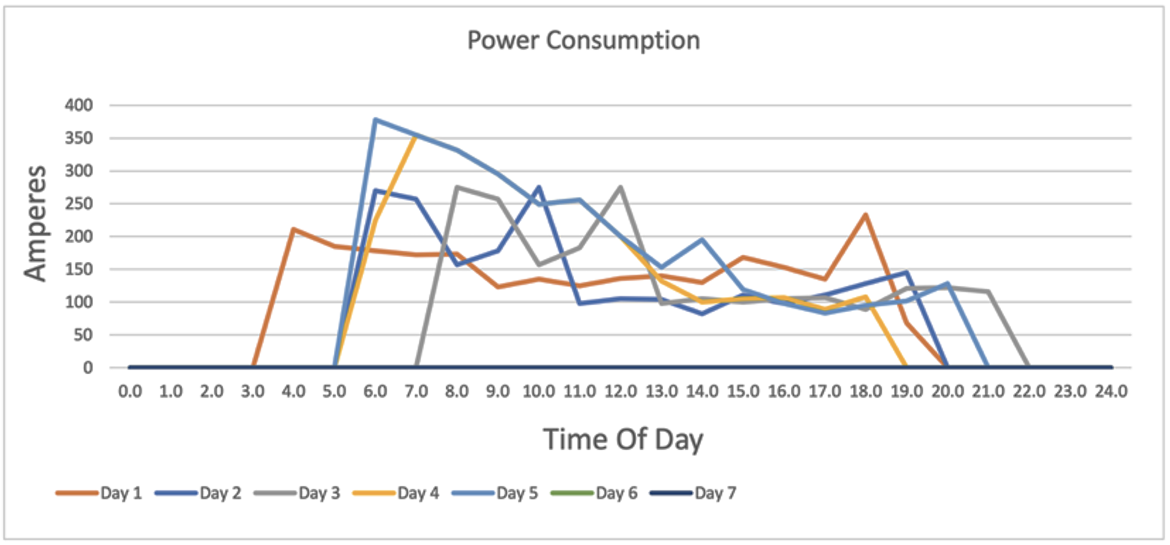

As can be seen in the power log above (Figure 1), the power drawn in basecamp is quite sporadic. Since there is time for heat to dissipate between peak loads, the power system can support more of them without overheating, which is why a BESS’s higher Prime Rating can be used when powering basecamp. Since, as can be seen in Figure 2 below, set lighting does not fluctuate much over time, and heat cannot dissipate when loads are continuous, the Prime Rating for a BESS cannot be used when powering set-lighting.

Instead, we must use its significantly lower (by as much as 20%) COP Rating, or the maximum output that can be sustained continuously without the BESS overheating or experiencing significant performance degradation. Which makes load profile an important part of this new paradigm.

Demand Factor:

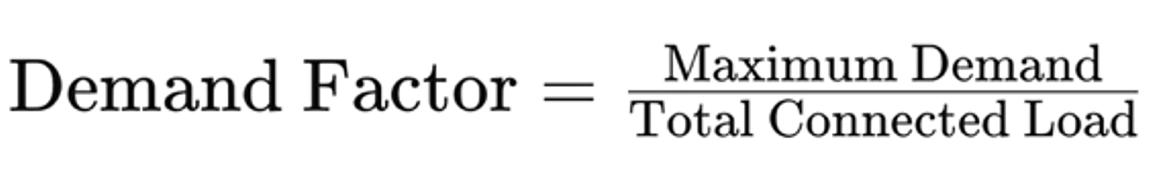

When sizing a power source and distribution system for a compound load, one of the first considerations is the system’s Demand Factor. While transformers and feeder conductors must, according to the NEC, have an ampacity sufficient to carry the load that could be imposed on them, their ampacity need not be equal to the sum of all connected loads since not all are likely to be “on” simultaneously. For example, an air conditioning unit and an electric heater never operate at the same time despite both being connected loads. In facilities such as hospitals, hotels, apartment complexes, and residences, it is unlikely that all branch circuit loads served by a power source or feeder will be used at once. Therefore, instead of sizing the power source and feeder cables to carry the full potential load of all branch circuits, a percentage—known as the Demand Factor—is applied to the total connected load. Demand Factor is the ratio of the maximum actual demand on a service or feeder to the total connected load. It is always less than one and represents the greatest probable load that the feeder will be called upon to carry and is expressed mathematically as follows:

Research and experience shows that the percentage of circuits used simultaneously varies widely by application. For example, the Demand Factor values in the NEC for general lighting loads is 0.35, 0.5 for general-purpose receptacles excluding dwelling units, 0.65 for commercial cooking equipment, and 0.75 for motor circuits. Electrical engineers multiply the total connected load by the Demand Factor to determine the load used to size transformers, generators, and main feeder ampacities – they call this the Sizing Load.

Deriving a Demand Factor for motion picture basecamps will result in considerable cost savings because a smaller inverter can be used since it only needs to handle the probable maximum load, not the total connected load. To illustrate how Demand Factors could be used to right size BESSs, consider a basecamp with a total connected load of 100 kilowatts, which includes multiple heaters, air conditioners, kitchen appliances, and lights. If all this equipment were to run at full power simultaneously, the system would require components (inverter and feeder cable) sized for 100 kW. However, applying a Demand Factor, say 0.4, reduces the probable maximum demand to 40 kW. This means the power source and distribution system need only to be sized for 40 kW, rather than 100 kW. Right sizing the power system in this fashion, results in cost savings without compromising the BESS’s ability to meet peak loads.

Diversity Factor:

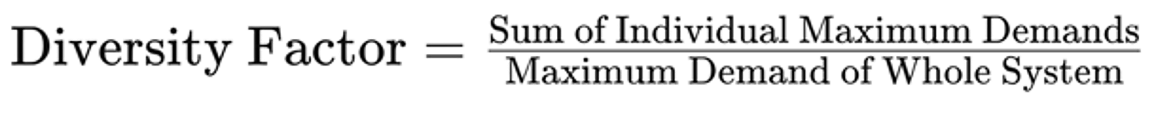

Diversity Factor is another important concept that electrical engineers apply when sizing power systems. It accounts for the fact that individual loads do not peak simultaneously. This means a power system does not need to be sized for the full probable maximum load (total connected load multiplied by Demand Factor) but rather for a smaller portion of it, allowing further reduction in system capacity and cost without sacrificing reliability.

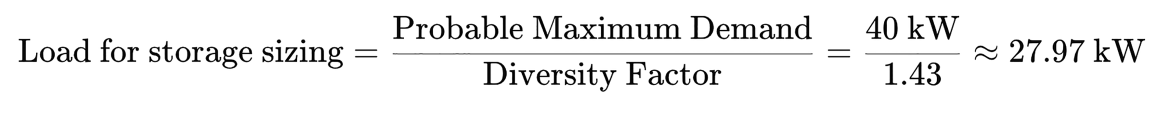

To go back to the example above, the individual maximum demands of the trailers summed to 40 kW when considered independently, but if the highest total system load observed is only 28 kW, the Diversity Factor is 1.43. This indicates that the system benefits from staggered or non-coincident peak demands, enabling a BESS to be sized for the actual energy likely to be used rather than the sum of its peaks. This often happens because different devices and trailers cycle on and off independently. The staggered operation reduces the overall load and allows for even more efficient sizing.

As can be seen in the power log of a movie set (Figure 3 below), set lighting does not benefit from load diversity because once turned on, they typically remain energized for long periods, meeting the NEC definition of a continuous load

As can be seen in the log of a basecamp (Figure 4 below), basecamp loads exhibit significant diversity, with power use cycling on and off unpredictably.

Not only do basecamp loads cycle on and off constantly, on a macro level there are typically periods of high demand and low demand. The period of high demand depends on the time of year and/or in what part of the country the production takes place. For example, in the Northeast United States during the heating months (Sept-May), the load profile of a mid-size basecamp consisting of the big three (HMU, Wardrobe, and Honey Wagon), plus eight star-trailers, will draw upwards of 200A/phase first thing in the morning as the heaters of all the trailers come online at once to warm them up. Once warm, the load of the trailers drops, as the heaters turn “off”, but is still high from crew prep activity. Between HMU blow dryers, wardrobe steamers, and Star Trailer microwaves warming breakfasts, basecamp loads can be as high 150A/phase until everyone moves to set, at which point basecamp loads drop further to about 50A/phase, or less, for the remainder and better part of the production day.

Things get a bit more complicated during the cooling season (June-Sept) when the period of high demand is during the middle of the day to cool the trailers. In the summer, the same mid-size basecamp can draw upwards of 200A/phase during high demand at noon to cool the trailers and then can drop to about 50A/phase off peak in the mornings and in the evenings when the trailer AC units are idle.

The application of a Diversity Factor will right size the storage capacity required for the notoriously slippery load of basecamps and result in further cost savings since a smaller BESS with less storage can be used without compromising reliability. For example, if the battery storage were sized for the probable maximum demand alone (as is done with IC generators), without considering the non-coincident nature of basecamp loads, one would think that energy equal to the blue + salmon areas in the Figure 5 below would be required, rather than the actual energy required - the salmon area since inverters only convert chemical energy to electrical energy upon demand.

As you can see in the illustration above, the over-estimation of energy needed (the blue area) can be appreciable – making it possible to use a smaller BESS with less storage capacity at an appreciable savings. Right sizing the power system in this fashion, results in further cost savings without compromising the BESS’s ability to support the load for an entire production day.

Demand Factor vs. Diversity Factor

Understanding the difference between Demand Factor and Diversity Factor is critical when designing power systems and sizing BESS for basecamp applications. Demand Factor reflects the actual system usage relative to the total connected load, helping to estimate probable maximum load for sizing of the BESS’s inverter. Diversity Factor captures the non-coincident nature of individual load peaks, allowing further optimization of system capacity by acknowledging that not all peaks happen simultaneously. Together, these factors will enable you to accurately size BESSs, avoiding unnecessary oversizing and reducing costs while ensuring reliable operation.

To go back to our example, if a basecamp has a total connected load of 100 kW, a Demand Factor of 0.4, and a Diversity Factor of 1.43, the probable maximum demand would be 40 kw (100 kW × 0.4). The inverter could then be sized around 40 kilowatts. To size the battery storage capacity to get through a typical 14hr day, take the probable maximum demand (40kW) and divide by the Diversity Factor (1.43) to get 27.97kwh.

Then multiply this by the number of hours (14) the system needs to be powered:

In this example, 392 kWh of battery storage would be required to power the basecamp for 14 hours. Applying these factors in this fashion ensures the BESS and power system are neither undersized (risking overload), nor oversized (which would increase costs unnecessarily).

Is it valid to assume that the Demand Factor and a Diversity Factor derived through profiling a few small basecamps as I have done, are representative of all basecamps? The NEC’s Demand and Diversity Factors are built from decades of empirical data, utility load studies, and engineering experience, where metered measurements of connected loads revealed that real-world usage rarely approaches the theoretical maximum in the tables. While we lack decades of empirical data, a motion picture basecamp trailer is not dissimilar to a residence in so far as it is a compound load likewise consisting of refrigerators, microwaves, heaters, air conditioners, TVs, and lights. Like in a residence, load usage in a motion picture basecamp is staggered as people cycle through activities that are part of a well-established workflow characteristic of all motion picture productions (trailers are opened, made comfortable, cast is fed, made-up, and costumed, before moving to set.)

While every basecamp has its own quirks, and every day follows its own schedule, in aggregate the behavior of cast and crew in motion picture basecamps is surprisingly consistent when viewed across many installations regardless of their size. This fact is evident in the daily power logs for a week on another show below (Figure 6.)

Even though the metrics captured on that show are for a basecamp consisting of a different mix of trailers, at a different budget level, operating on a different schedule in a different part of the country, they are surprisingly alike and like the basecamp I analyzed.

Two basecamps—one small, one large—will follow the same usage profile because demand and diversity comes from the human usage patterns of an established industry workflow, not the number of trailers. For instance, just because a neighborhood is large does not mean every home’s appliances will run full tilt all the time. A larger basecamp simply scales up the same usage profile. And surprisingly the ambient temperature outside has little effect on the heating/AC load because human nature is, well, “human nature”. For example, in the basecamp profiles I conducted the energy consumed by the Wardrobe trailer on a cool day (760), a warm day (850), and a hot day (940) revealed that, surprisingly, it required less energy (64 cycles of the 4-Ton Bard AC unit) to cool the trailer on the hot day than it did on the cool day (which required 76 cycles), because on the hot day the crew were more likely to keep the door to the trailer closed. Leaving the door open on the cool day resulted in the AC running more frequently.

Like the NEC tables capture typical load usage in other industries, allowing systems to be sized for realistic peaks rather than the sum of all connected loads, Demand and Diversity Factors built from empirical data, load studies, and the collective experience of motion picture Basecamp Genny Ops, will enable us to accurately size BESSs for motion picture basecamps. But further investigation will be required before the Demand and Diversity Factors I have derived can be taken as representative of all basecamps. It may be that there will be one set of factors for heating season and a different set of factors for cooling season since the predominant load for each will be different (AC units for cooling season, and resistive heaters for heating season) – but maybe not since the electrical load of a resistive heater, and its duty cycle, is similar to that of an air conditioner. Only the analysis of more basecamps will tell.

In my opinion, further research is warranted. Taking the guess work out of sizing BESSs for basecamp power by applying an established Demand Factor and Diversity Factor to a Total Connected Load provided by the basecamp trailer vendor, will take the risk out of using BESSs to power basecamps – making them a viable source of sustainable power.

Caveats:

Since Level 2 EV chargers are continuous loads by the NEC definition, when charging EVs in basecamp two calculations, one for the non-continuous loads of basecamp trailers and another for the continuous loads of the EV chargers, will be required. For example, in this case we would first calculate, using a Demand and Diversity Factor, the amount of storage capacity required for the non-continuous loads of the basecamp trailers; to which we would add the amount of storage capacity required to charge the EV s not using these factors since Level 2 EV chargers are continuous loads by the NEC definition.