Getting to Net-Zero Production: Part V

The introduction of mobile Battery Energy Storage Systems (BESS) has led to a paradigm shift in how power is sourced, distributed, and managed on movie sets and in live events. For example, in part one of this series (18 Sep 2024), we discovered that it is possible to get to net-zero production with mobile BESSs that can be paralleled to increase capacity and runtime.In part four of this series (17 June 2025), we discovered that not just any mobile BESS will serve our purposes but one optimized for grid forming with sophisticated load-adaptive algorithms is required. In this part we discover that the transition to clean sustainable set power is not without challenges.

Here’s one challenge: BESSs do not generate sufficient current under fault conditions to integrate with the selective coordination of breakers in motion picture distribution systems which are engineered around the much higher fault currents generated by diesel generators.

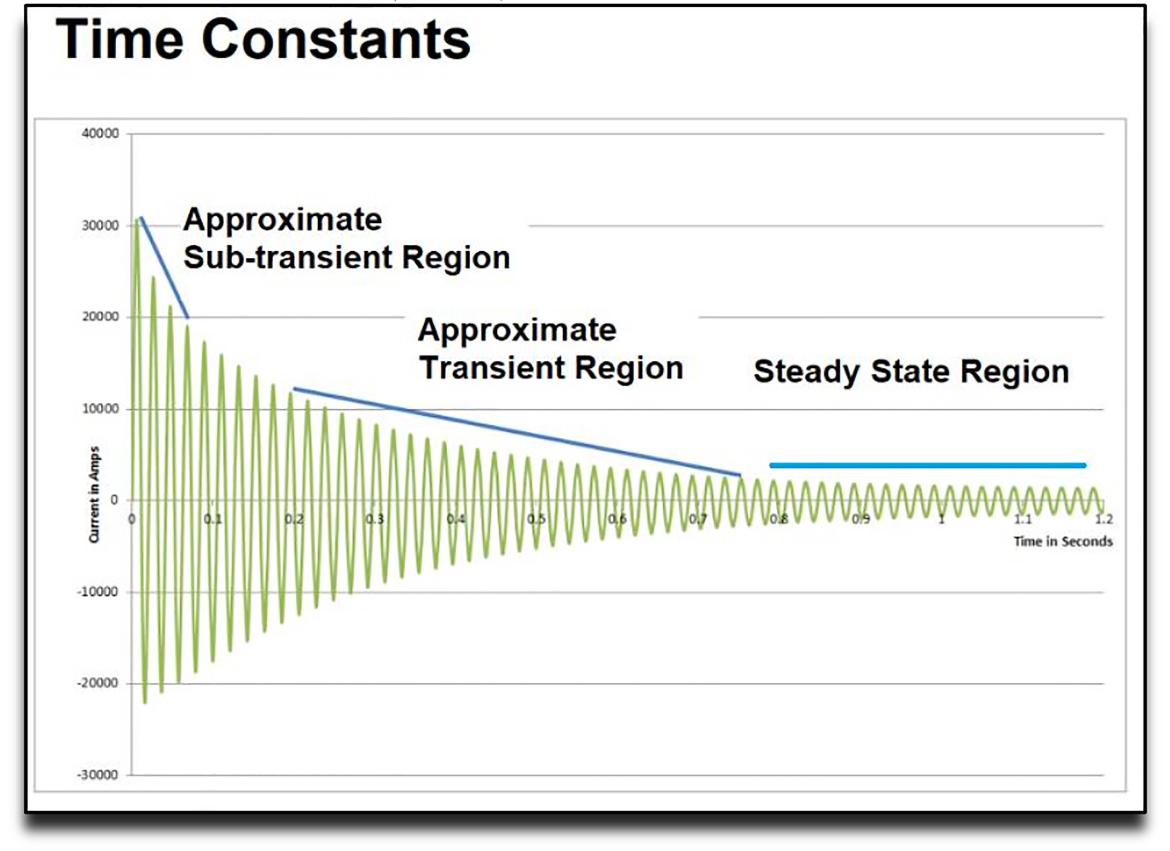

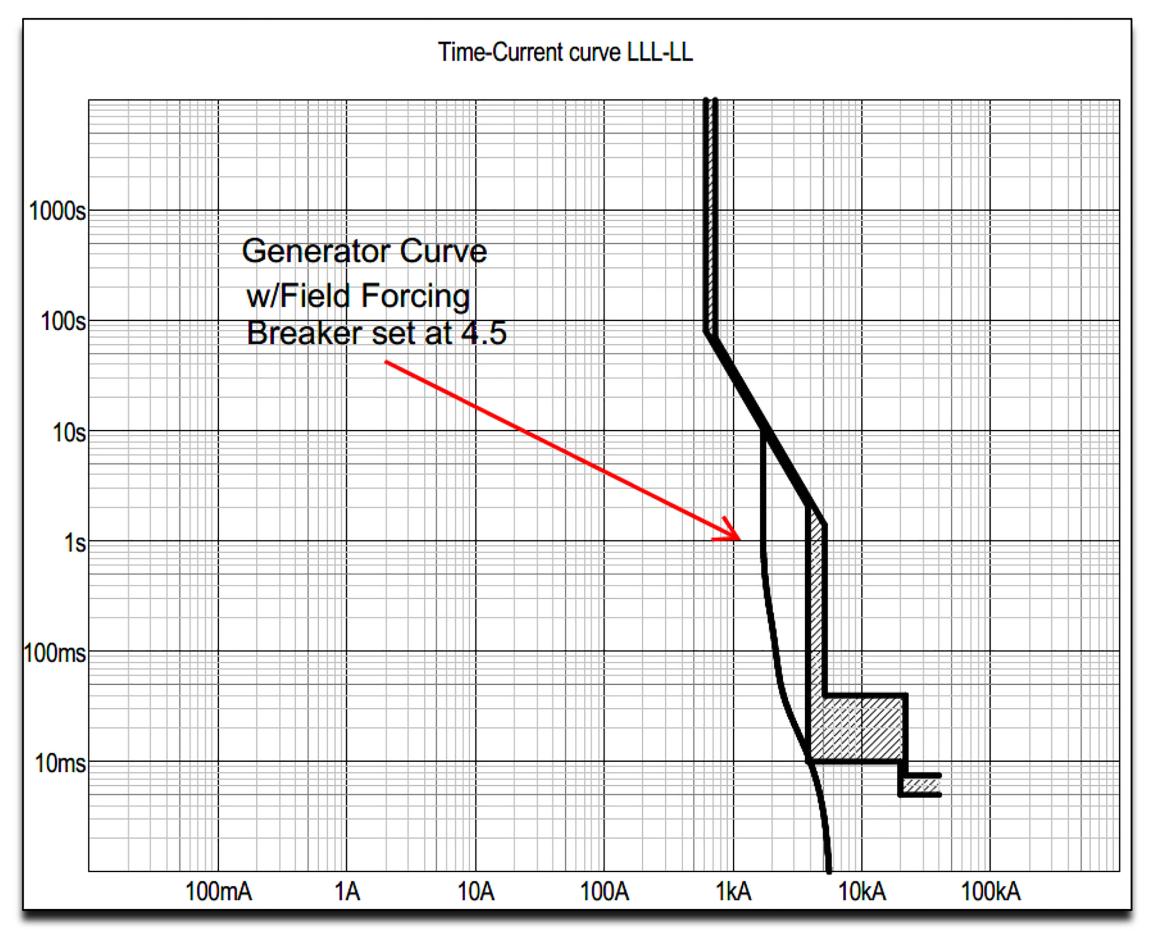

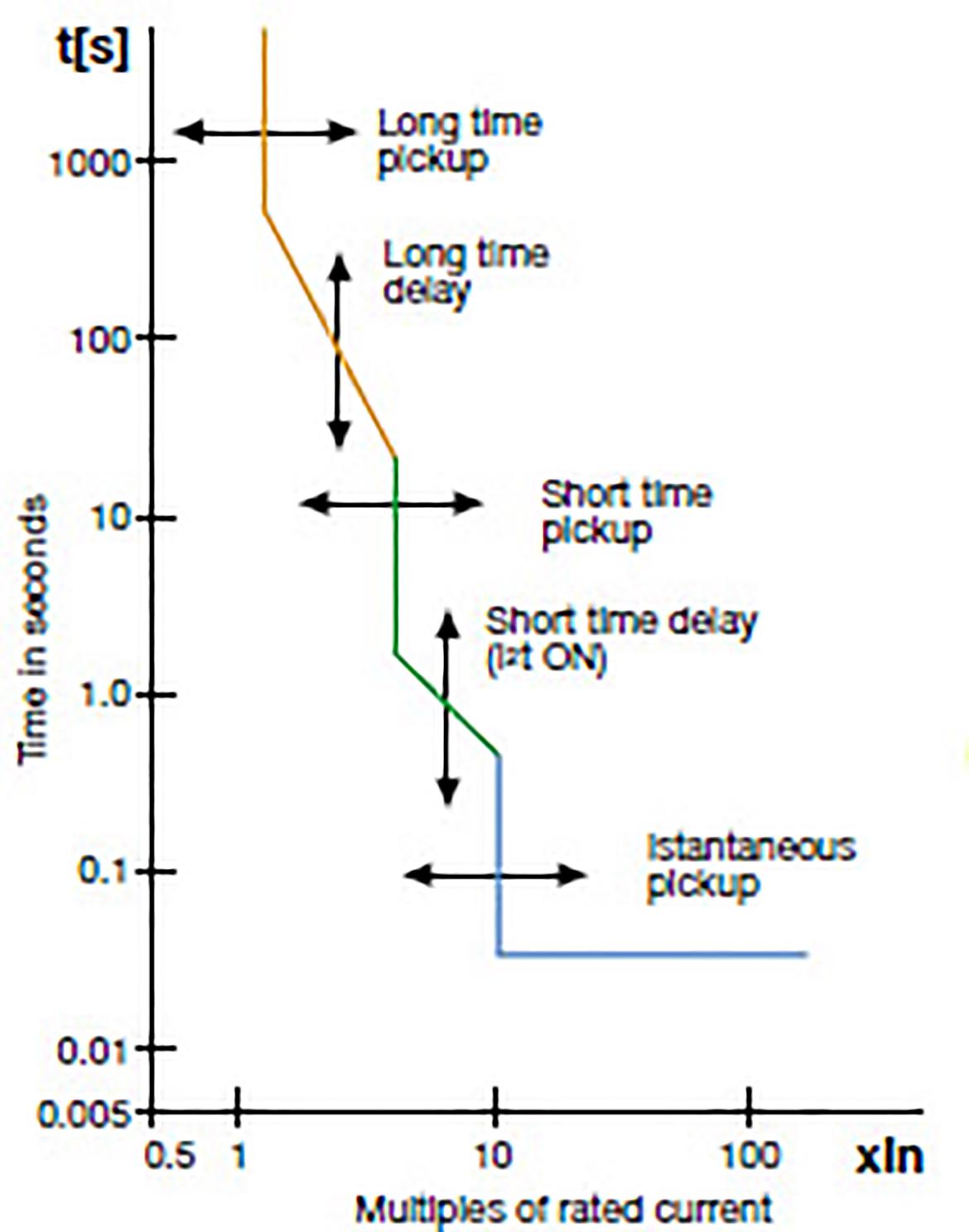

Diesel generators produce high fault currents — 5 to10 x their rated output. As can be seen in Figure 1 above, this high fault current is sustained for hundreds of milliseconds to a few seconds and provides enough energy to reliably trip the types of breakers (high in-rush, long delay) used in our distribution systems. This becomes evident when we plot the decrement curve of a diesel generator against the time/current trip curve, or TCC, of a typical breaker used in our distribution systems (Figure 2 below).

The decrement curve above shows a maximum short-circuit current of approximately 5530A/phase for about 10ms, which is about 5 x In, (where In stands for rated current,). The current then decays to about 4500A/phase (about 4 x In) in around 600ms, and eventually to a steady state current of about 2000A/phase (about 2 x In). The steady state current will persist until interrupted by an over current protection device (OCPD). Since the peak fault current of 5530A reaches the instantaneous trip threshold (I) of the breaker, it will trip in a timely fashion – isolating and clearing the fault before it can affect the entire system and damage can be done.

BESSs exhibit very different fault current characteristics. Lacking the significant inductive reactance of a diesel generator, BESS inverters have extremely low impedance and radically different fault current behavior. According to Ohm’s law (V = I x Ω or I Fault = V ÷ Ω), the extremely low impedance (Ω) of BESSs would normally result in extremely high fault currents (I Fault) that would damage their electrical components. Manufacturers of inverters address this potential for high fault currents by implementing several protection strategies.

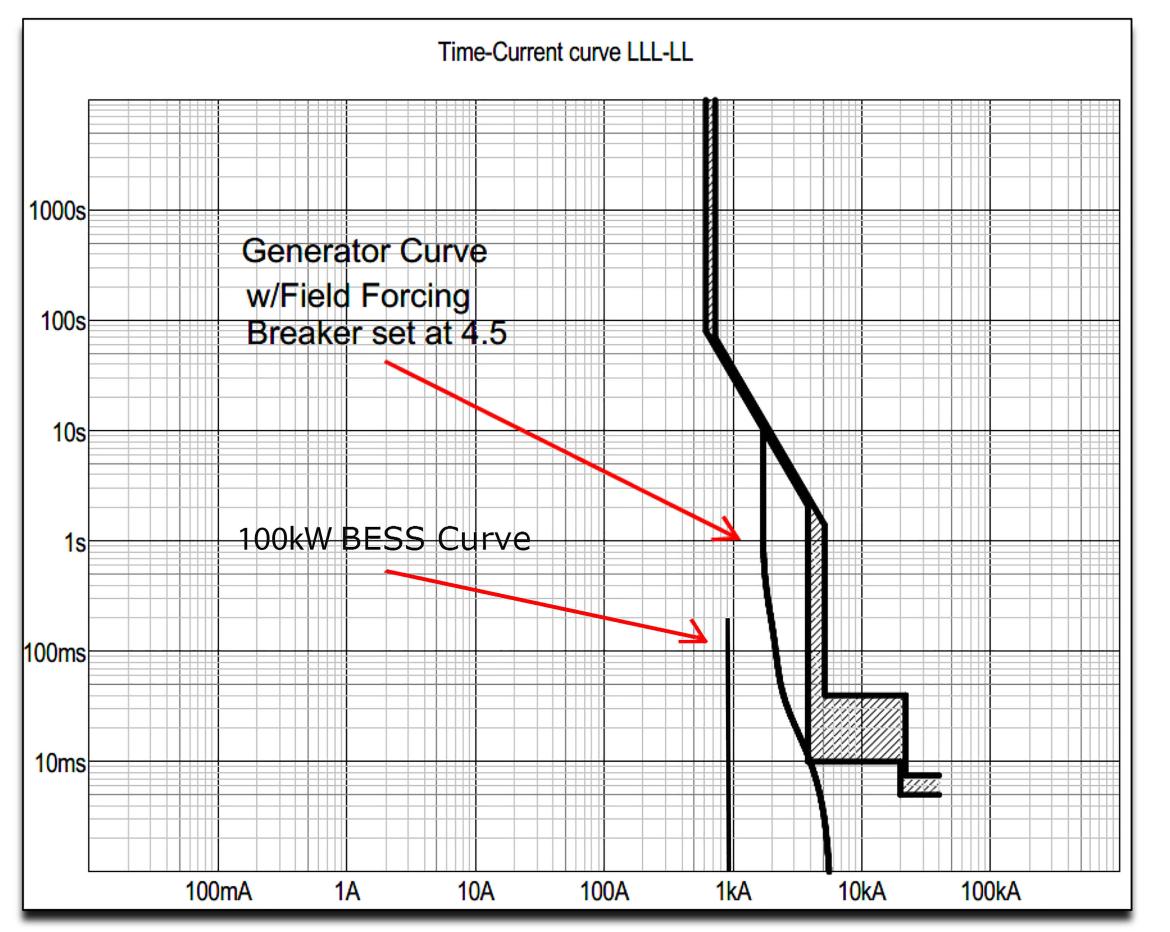

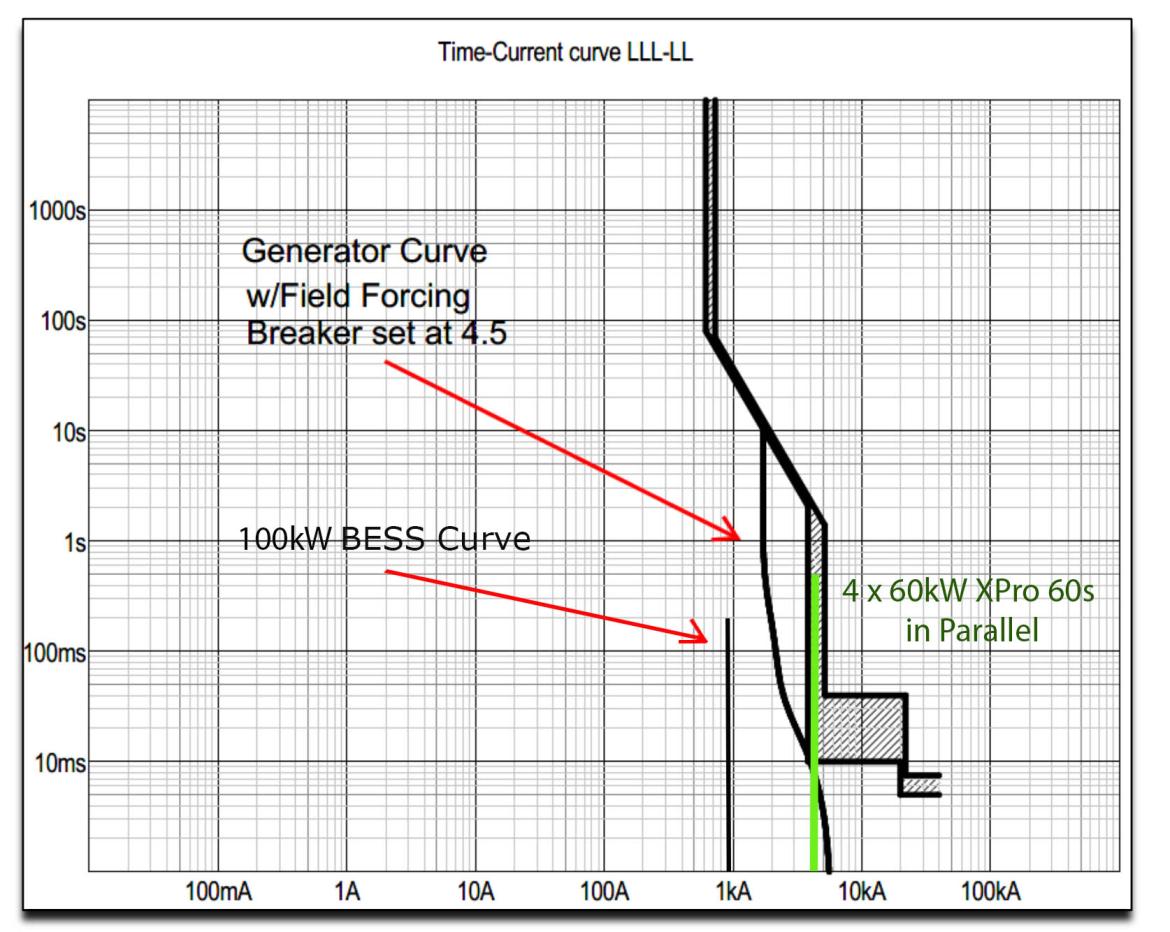

The Power Conversion System, or PCS, of grid-forming inverters that interface directly with AC loads have built-in current-limiting features. This means that even if the inverter is capable of producing extremely high fault current, the PCS limits the output current to prevent damage to its electronic components. A survey of grid-forming BESSs reveals that the trip threshold and time delay of PCS fault current protection varies widely — ranging from 1.5 to 3.4 × Iₙ compared to the 5 to 10 x of diesel generators. And the fault current of BESSs typically times out in 100 to 500ms (6 to 30 AC cycles) where the fault current of diesel generators will persist until interrupted by a breaker. For example, of the BESS surveyed, the one with the highest fault current (3.4 x Iₙ) with a 100kW inverter, produces a fault current of 944A/Phase for only 200ms. Since it does not reach the trip threshold of the high inrush/long delay breakers used in motion picture production (see Figure 3 above), this lower fault current of only 944A/phase will not cause this breaker to trip because it does not persist long enough.

Why does this matter?

A fault current that low will not trip downstream breakers in the tiered fault protection system we use because it is engineered for the high, persistent fault currents of diesel generators. To see why, let’s look at a concrete example.

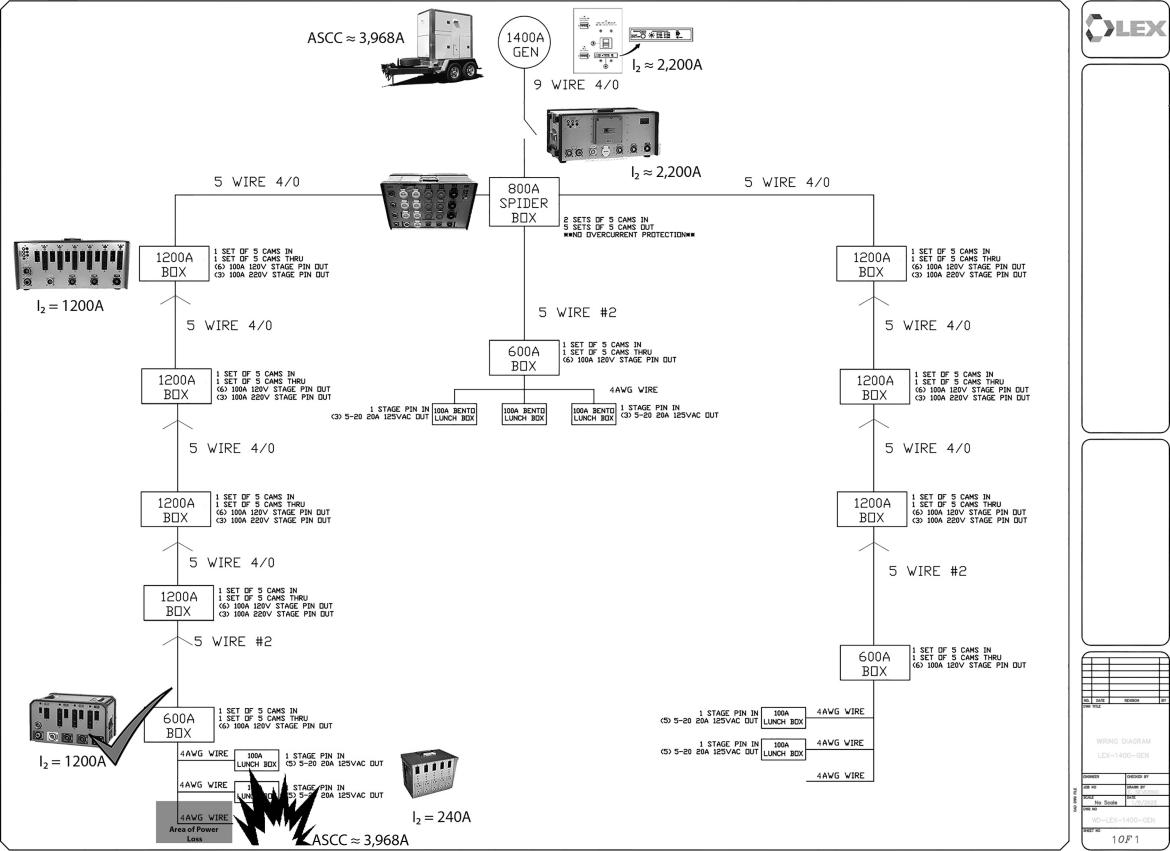

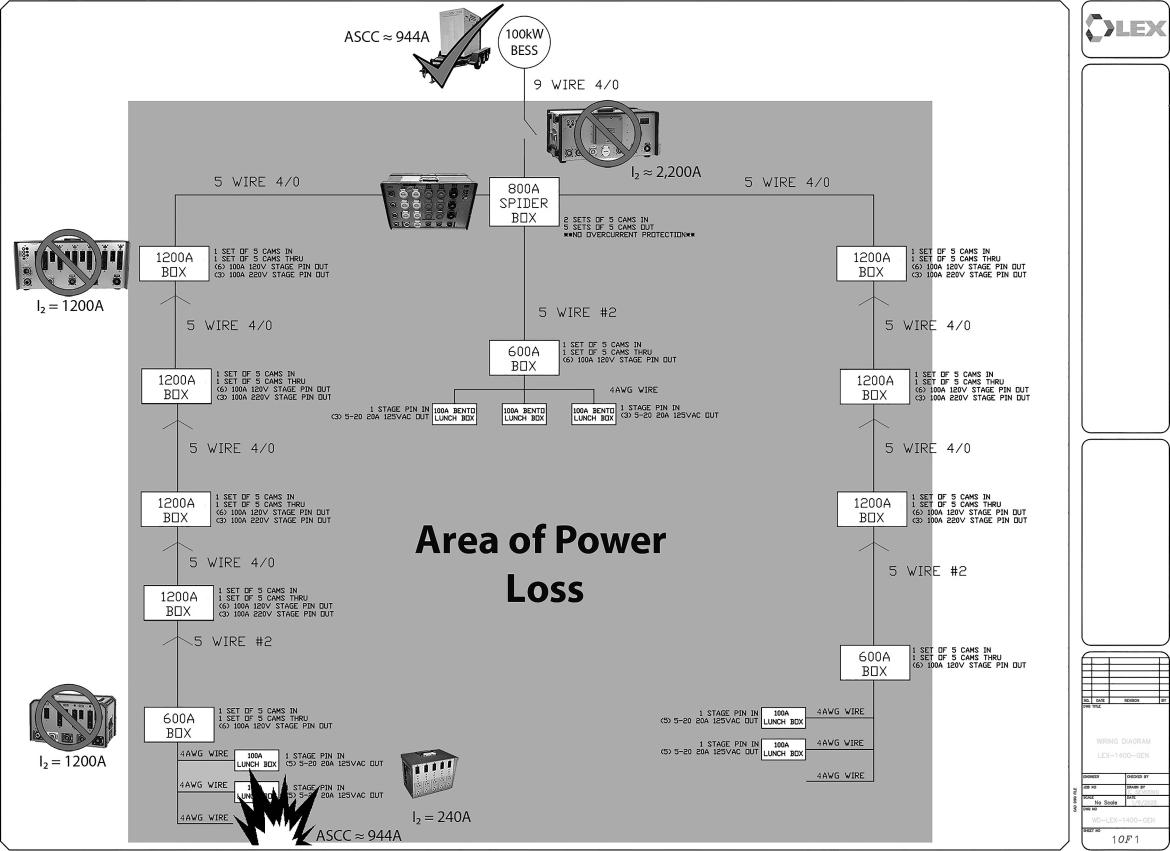

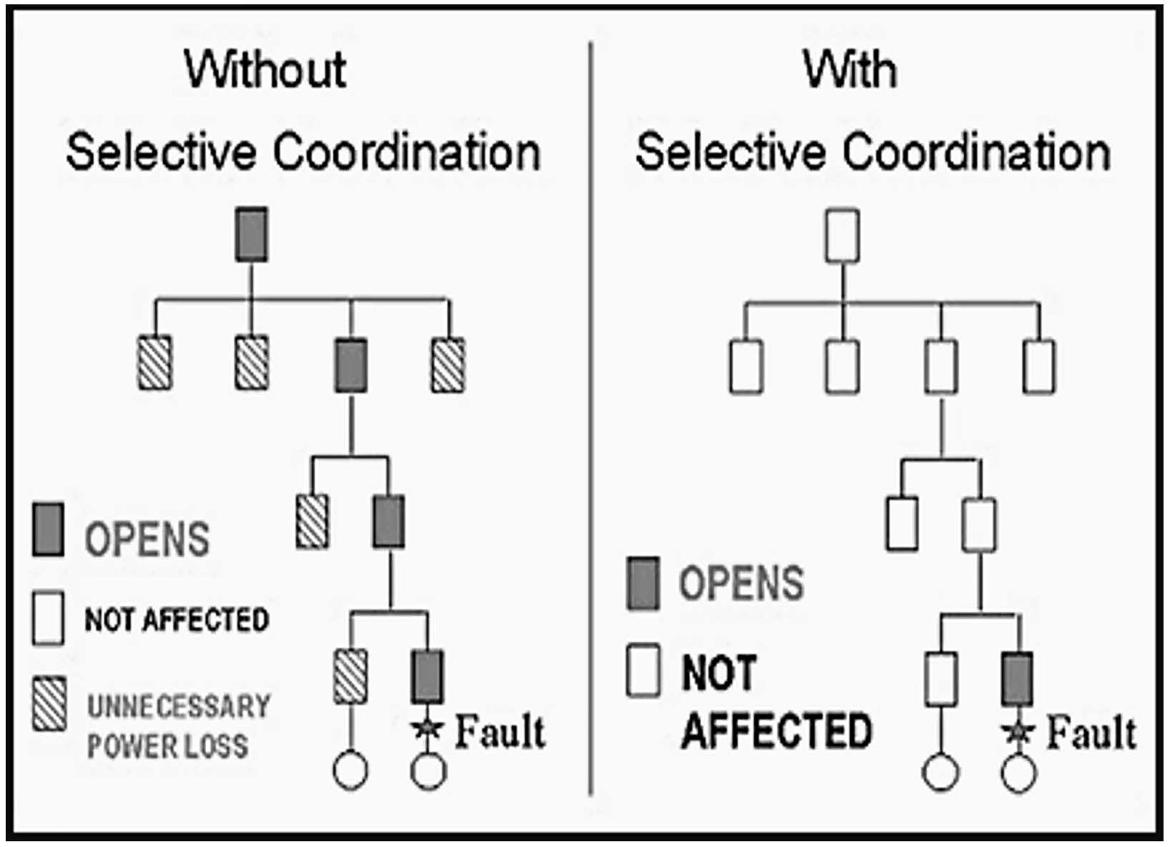

Take for example the library set of Knives Out. From the one-line drawing of this distribution system (Figure 4 above), we see that the motion picture industry uses high trip thresholds with long delay to allow for the high inrush currents of big incandescent lights, the locked rotor inrush currents of motors, and the inrush current required to charge large capacitor banks. It is worth noting that the breakers are selectively coordinated to isolate faults to a branch circuit so as not to lose power to the entire system.

Let’s now look at how aligned the limited fault current of 944A/phase generated by a 100kW BESS (with an I Fault = 3.4 x In ) is with this selective coordination of tiered breakers engineered for the high fault current of diesel generators. This is a critical issue, not only because all the electrical distribution equipment we use is engineered for the high fault currents of diesel generators, but also because BESSs will be used in conjunction with diesel generators in hybrid set-ups – so they must be able to drop into existing fault protection systems engineered for the high fault environment of diesel generators.

When we game out) what would happen if a fault occurred on the Knives Out library set, if the set were powered by a 100kW BESS (with an I Fault = 3.4 x In ) instead of a diesel generator, we see the problem in Figure 5 below. If the fault occurs in a piece of low power equipment plugged into a 20A branch circuit of a lunchbox, the hydraulic-magnetic breaker in the lunch box protecting the circuit, with an instantaneous trip threshold (I) of 240A/phase, will trip instantaneously under the 944A/phase generated by the 100kW BESS - isolating the fault to the branch circuit. But, if instead, the fault occurs while patching a large load into a 100A Bates receptacle of a 1200A box, the hydraulic-magnetic breaker protecting that 100A circuit will not trip instantaneously because 1200A/phase is required to trip the breaker. So, rather than the breaker tripping instantaneously – isolating and clearing the fault - the fault current persists.

In this one-line drawing, the next breaker upstream is the ABB T-MAX breaker in the portable disconnect immediately downstream of the 100kW BESS. Configured for a trip threshold of 2200A/phase, the ABB T-MAX breaker will also not trip under the 943.77A/phase generated by the BESS. So, rather than the T-Max breaker tripping and clearing the fault, the fault persists until the PCS overcurrent protection of the BESS times out and stops generating power (It's worth noting that the ABB breaker will trip instantaneously under the fault current of 3,968A generated by the 165kW generator).

Why does this matter?

Not isolated to a branch circuit, the fault activates the PCS’s fault current protection and power is lost to the entire set. For lack of selective coordination, the crew of Knives Out would be literally and figuratively in the dark where the fault occurred. Production would have to stop while the electrical crew powered each branch circuit in isolation until they found the one with the fault that caused the BESS to shut down – which could disrupt production for hours. Or, worse, say the electric were injured when creating the fault, then the total black out and unknown location of the fault would impede the Set Medic finding and giving aid to the injured electric in the dark.

This issue pertains to more than just safety on set. Say a show has set up a 6-port charging station (two 80kW Level 2 Chargers per phase) powered by a BESS. Each charger is plugged directly into a common bus (Cam Spider Box) supplied by the BESS. In the event of a fault in one of the chargers, the BESS will shut down and catastrophe - no cars get charged.

What can be done?

Even though software-based PCS protection allows for a wide range of adjustments, it is ultimately constrained by hardware capabilities, thermal limits, and safety standards, and so BESSs are unable to generate the same fault currents as diesel generators. So, what is required to make sites powered by BESSs safe is a two-prong approach. First, a re-configuration of the fault current trip settings of the T-MAX breakers used in our portable disconnects.

But since too low a setting could lead to nuisance tripping from transient inrush currents, using BESS that generate high fault currents and can be paralleled to increase the amount of fault current generated is also required. Let’s look at each prong, starting with reconfiguring the T-MAX breakers used in our portable disconnects.

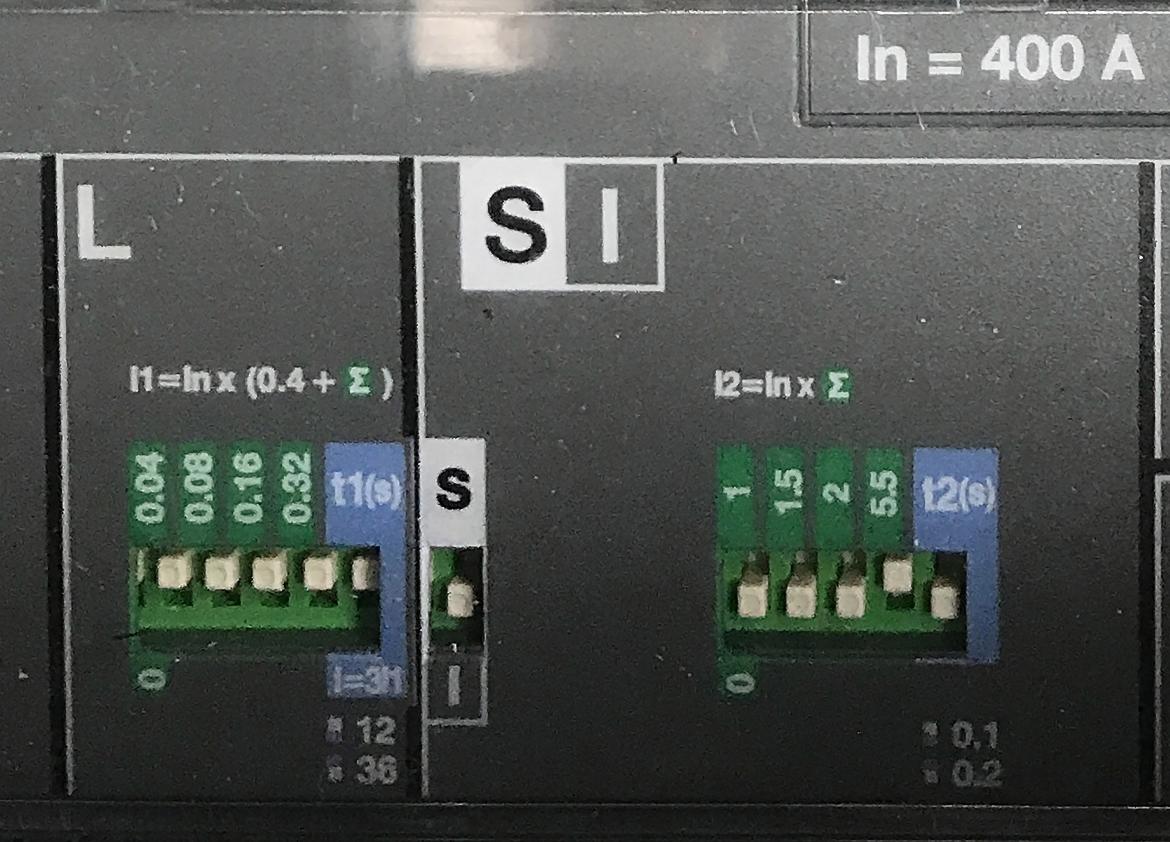

The dip switches on the ABB T-MAX circuit breakers (Figure 8 above) can be used to configure various protection settings. These settings include adjustments for long-time (L) and short-time (S) overcurrent protection, as well as instantaneous trip thresholds (I). With user selectable instantaneous trip settings (I) of 1, 1.5, 2, 2.5, etc. to 10 x In, the T-MAX breakers of our portable disconnects can be re-configured to align with the low fault current characteristics of BESSs. Alignment requires that it be adjusted so that the total interruption time of the T-MAX breaker is shorter than the response time of the BESS protection system, ensuring that the T-Max breaker in the portable disconnect trips first during faults downstream of its location.

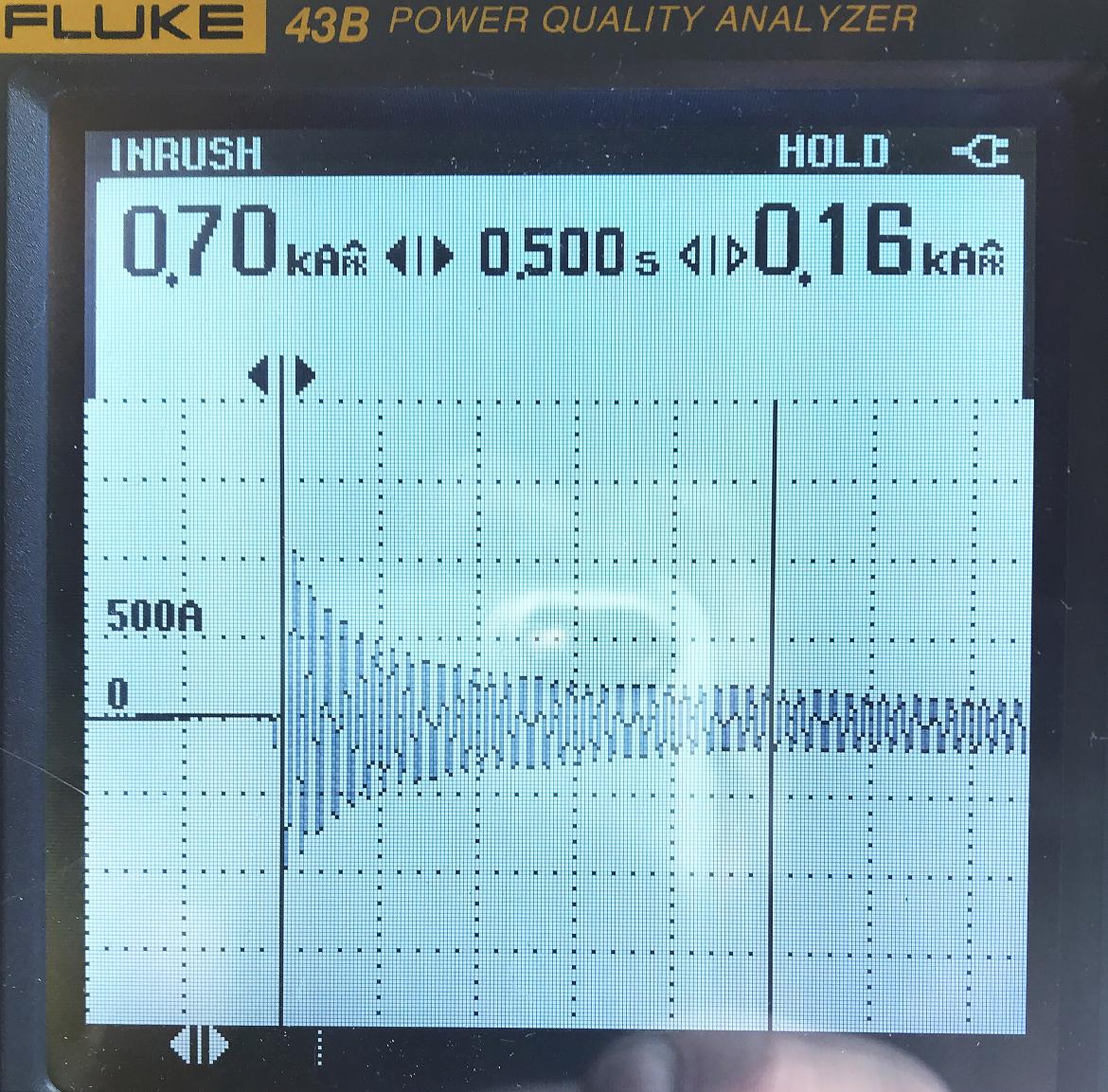

While T-Max breakers can be aligned with the low fault current generated by inverters, the breaker will nuisance trip under high inrush current loads if the instantaneous trip parameter (I) is set too low. The one load whose inrush current presents the greatest challenge is a 20kW Incandescent Fresnel. When first powered on, an incandescent lamp's cold filament has a much lower resistance than when its operating hot. This results in a high “cold resistance” inrush current at startup. Depending on the filament's thermal mass, its inrush current can be 5 to 8 times its steady state current and persist for several AC cycles as the filament heats up to its operating temperature. As can be seen in the measurement of the inrush current generated by a preheated 20kW filament (Figure 10 below), the peak inrush current persists for about 100ms (6 AC cycles at 60 Hz) before it decays to 50 percent.

The problem is that breakers can’t distinguish between fault and inrush currents and will nuisance trip under such high inrush current if the instantaneous trip threshold (I) is set too low. Which is why you must use a BESS with the highest fault current possible. The more fault current generated, the higher the instantaneous trip threshold (I) can be set on the T-Max breaker, creating more head room for high inrush currents to pass without nuisance tripping the breaker.

By both increasing the fault current generated and reducing the instantaneous trip threshold (I) of the T-Max breakers in our portable disconnects, we can use them to partition our distribution systems and restore selective coordination so that only the breaker closest to the fault trips, without affecting power to the rest of the distribution system as illustrated above in Figure 11.

Paralleling BESSs

Paralleling BESS is another solution. There are many compelling reasons to parallel BESSs, but this has got to be the most compelling. The fault current of paralleled BESSs is additive, so paralleling smaller BESS, like the PowR2 XPro 60, can generate sufficient fault current to trip the breaker closest to the fault - isolating it to the branch circuit as intended.

The grid-forming inverter used by PowR2 will generate 2 x In for 500ms. The In of the XPro 60.120.208 is 166A, so it will generate 332A of fault current. Four in parallel will generate 1328A – more than enough fault current to trip down stream breakers engineered for the high fault currents of diesel generators (see Figure 14 below).

Had the Knives Out set been powered by four PowR 2 XPro 60s operating in parallel, the accumulative fault current of 1328A/phase would have been sufficient to trip the breaker closest to the fault. The crew of Knives Out would not have been left figuratively and literally in the dark where the fault occurred, and the Set Medic would have been able to administer aid to the injured electric. In the case of the EV charging station, five of the six cars would continue to charge. What would have been a catastrophe is now just an inconvenience.